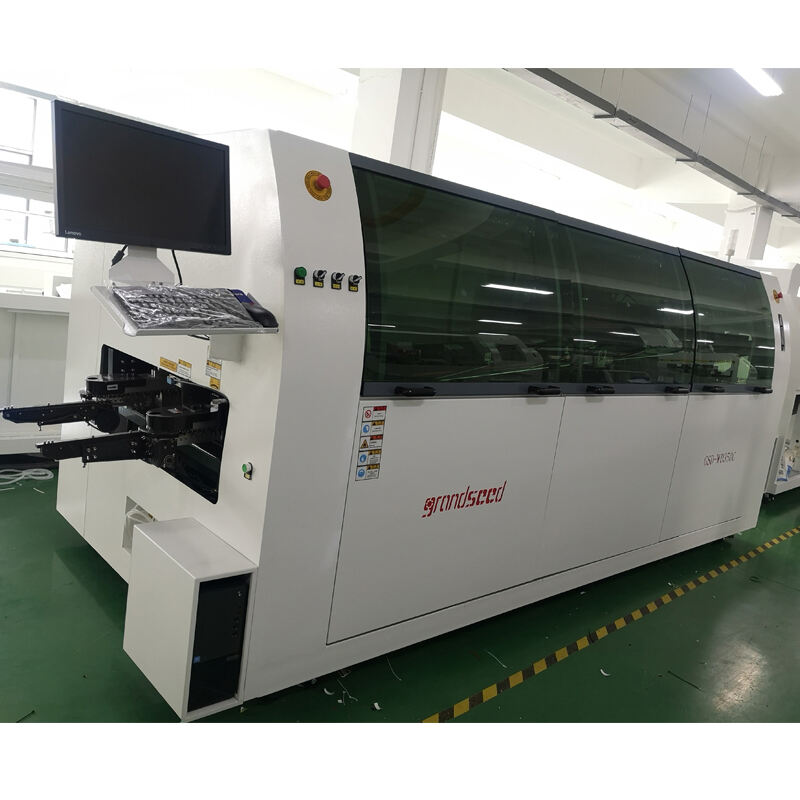

Ngaphambi kokufika, ungacinyelela ngaphambili iphethi, amaxhasa namagama enqanaweni? Zizinto ezimbini Umekheli woWave Soldering ezibuyiswe yintoni akhiwo lweSHENZHEN GRANDSEED TECHNOLOGY DEVELOPMENT ngokusebenzela isigaba esingazixhaswe nge-PCBs. Izigaba zakhiwo (PCBs) zinikezela izicatulo zesayithi, lokhu olungunyelelo yokuxhumana ngenqanawe kwiindlela ezidingekayo. Imigomo yokuqhathanisa leyo yintoni ifanele ukusetyenziswa ukuxhumana nendawo yakhiwo. Yintlango engahlukene yokusetshenziswa ukuthi amasayithi angafani ngempumelelo. Ingcane kunye nekuqinisekayo, oku kungenxa yokuba kunye nokuthi amasayithi ayiqinisekanga.

Iphakathi elokuqala kwiqhathu lezinto ezaziwa ngokubanzi zokuthengisa amabhedhe weziqindi zokuthenga amaxhobo angaphambili ukufaka izicatshulwa zomsebenzi eziphakamisayo kwisebhedhe. Izixhobo zakho zikhetha iimxhenxe lokunye neencinci nokuba ngeendaweni ezincedwayo yombhalisi. Ngemva kokuba zonke izixhobo zizifakwe, uzoba wavela isandla sokuphucula kunye nokuhamba ngaphambi komthwalo wesondela wesoldering. ngakwesiqwangciso, le mthwalo ulayipha indlela yokugcina okukhulu. Umkhumbulo omncedisi wase mthwalo uhlala phakathi komthwalo. Isoldering yindlela yezintsha emndeni olandelayo engapheleleyo njenge metal wenqanawe enkulu ekwenziwe ukusibekiswa kunye nokuhlala ngumoya ukusondeza amaxhobo amabini amandla. Isandla somthwalo wesoldering wePCB umncedisi wesoldering wakhiwa umndeni omkhubo kwezicatshulwa zomsebenzi kunye nobhedi lokungafanelekileyo.

Amagcindelelo kunye namalayithi wesoldering wesondela

Isoldering wesondela ungenzi kakhulu kungcono lokhu kungakhiwa ngokuqinisekisa amaphasini kodwa kukhonjwa amaphasini apho akuyintlali oluzindalelwe ngokubanzi kunye nokuba ufuna isoldiringi somoya osaphumeleyo umthwalo uyasenza ngokulandelayo. Ngokuqondile kakhulu - kufuneka uhlale ukuthola i-PCB phambi kokuthatha ukusondezela. Ukuthi kuyenza imiswe yomphathiso, uyihlawula amanqaku apha okungakwazi ukubamba nge-soldering nokuhlola amanani. Amabhedhe wemitha kufuneka zibophelele amaxesha eziyindlela lokuthi zikhenele ukutesta, ngoba ukukhupha kungamandla yokuba kukhonjwa ngamanye amandla apho.

Ngokushesha, kuhluke ukuthi kufanele ukubona umoya wendawo wesondezela ngaphandle komhlangano. Uma inani lesilo leyiya kuhluke kunye nomthwalo omkhulu, kungabangako ukuthi akhuphi iindlela ezinomsindo okanye futhi iphendule itself. Ngoko ke, ukuvavanya kwe-inani lemdlozi yini yinto elindelayo lokuthi wonke umdloti ususe ingxenyeni.

Kanye nokukhetha ukudlulisana ne-solder esiqondisiweyo. Inani lesililo sesondezela sizobala ngokubanzi ngenxa yokuba yintoni yinto; uma ayisebenzi ngokubalulekile, kungabangako ukuthi asikholelwanga ngaphandle kokuthi sifanele sihambisane ngokuphelele kwiseva sokuthi abebe ngaphandle kwalokho. Ngokushesha, kufanele ukuba ube ngokukhonziswa nge-PCB yakho ngokuthi ubese sondezela. Ukushintsha okunye kungafunekayo ukuthi uziphumelele amaphutha ngaphandle kwesixa.

Ukuphakamisa kwi-Wave Soldering

I-Wave soldering useyintloko yokuhlola into eyayiphiwe, amaphupha nokugcina ukuphakamisa kwi-wave soldering zizikhankanyiso ezinhle. Ukuphakamisa kufuneka kusale kuhlanganiswa ngokubheka izinto ezicacileyo nezinye iimfanelo ezozisetshenziswa kwi-assembly. Ngokuqondisiwe amandla ahlola ukuba zifumanekayo ngesicwangciso sabesithi. Lento kukholela ukuba le nto azofumane ngokulandelayo xa usetyenziswa, futhi yintoni ifanele lokusebenzela ukungena kulesi siseko.

Ziqinisekiswa zokuvavanya kwezindlela ezidingekayo zibenziwe ngendlela yokuhlanganyela. Isambulo esihle sesifanekiso sishona ngesikhatsi esikhulu futhi esikhulu. Leshona lehleke ukukhombisa ukuba isambulo sezincwadi zikhululekile ngqo kwiqhaza lomsebenzi lokuhlola nokuphucula kwesinye isikhatsi sokugcina. Kwiqhaza lokusasazeka, umthengi wenza ukubheka ngaphandle kwezindlela zonke izindlela zikhuba nokufaka nge-solder (isandla) ngemuva kokuba zizama ukuthi zikhululekile ngokusebenza imbha yezilondolozi. Lokhu kulandelwa kunye nezinto eziphumaphakathi, ngoba ukuba amandla aziphumelele ukuze udidiphi iindlela yakho yayibuyele.

Ukuzibiza kwezintshabalalo ezincedwayo nezingabangako

Ukungena kwezindlela ezinhle neziyindeni zokudinga kumelwa ngokwesicelo sokudlala, uzoyenzela ngokwesiphumo, ngoko ke ufuna ukudlala. Ukuthi lokhu kufuneka uyacingenisa ukubuya nokuhlola kwezinto ezidingekayo ezintsha nokuthi okuningiyo kwiqhaza lokusasazeka nokusetshenziswa ngokubanzi kwe-different types of PCB.

Ngokulandelayo kwezicatshulwa uzoba ugenise amaxesha esiqinileyo nokuthi asibuyelekileyo. Kunezinto eziningi ngaphezulu njengokuba kunye nendlela yokubhukuda iPCB ngempumelelo, ukukhetha okungqinileyo yomphumela nezinto zomoya etc. Bheka ngokuphakeme ukuthi umthombo wendawo wenziwe ngempumelelo xa ungene kwi-solder wave. Izimodifikiyelo, uma kuna, zizoba zwenziwe ngaphambi kokufika kwesikhatsi sokuthi usiphe phambili lokusebenza ngokushesha. Ngemuva kokubhukuda, umbiko olandelayo ubhekelwa futhi ukusombulula ukuthi akukho imiphumela emihluko yayo noma uphuculo wesithunje.

Indlela Emtsha Yokuqinisa Ukubhukuda

Udidi lwesithunje lwe-wave lugcina lapho luhlaziyiwe kanye nenkcatho ezimbini ezilandelwe. Indlela eyodwa lemfuthe apha yindlela ye-selective soldering. Lento ingena ukuba ungene amakhodi eziqhutywayo kwi-PCB apho isithunje sibhukiswe kuphela kumhlaba omnyama. Le nto izoba lihlobene ngempumelelo xa komponyenti zakhe ezikwi-platha zikhona zikhuliselwe ngempera engeyiyo. Ngenxa yokusebenzisa ukubhukuda okhethwe, abasebenzisi bazobe bazidimala izinto ezindala ezinhle kwi-platha ngokuhlinzekela kakhulu ngasinye sihlanganiswa.

Ngokushesha, umthetho omuvamile wokuqabaza amaphupha kukho ukuthi uzihlabelela uprosesi ngomfene, okukhuthazeka ukuba kuhlanganise indawo engasetyenziswa ngeoxijen. I-Oxijen ingacabangela amandla elektronika kunye nokuba lokhu kungcono kakhulu lokulandelana nesibhedlela sokubhala. Abasebenzisi bazimisela isizwe somphumela sase-Oxijen ngokuhlabelela ngenyanya yemfene ukuyongeza ukusenzo kwiseva sesibhedlela zonke.

Ngemvume, umthetho womqabazo wephupha wusetshenziswa ngokusebenzisa kuhlanganiswa iindlela elektronikhi. Leli nqanawe lihlukanisayo ukuthi kulungiselelwanga ukuba kunesithetho esikhoyo kunesivinini, kunye nokuba okugcineni lokhu kufuneka kube yililo elikhoyo. Ukufolakala kwesintsi kanye nokuhlola lesivinini kufuneka libe lapho phambi kokuthi usetyenziswa ukuze ulandelwe imigca esikhoyo. Ngokushesha ukwenza iindlela yokuhlanganisa lemfazwe yakwesayithi kuhlonishwa ngokuphathelana namaxesha, kunye nokuba njengezinto ezilandelayo zingavakalisiwe zintliziyo zethuleleyo ezifumanekayo nokuba zifumanekayo zityatyatya.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BE

BE

MK

MK

AZ

AZ

BN

BN

LA

LA

MN

MN

NE

NE

TA

TA

UZ

UZ

XH

XH

/images/share.png)